Towel Manufacturers Association of Pakistan

ٹاول مینوفیکچررز ایسوسی ایشن آف پاکستان

-

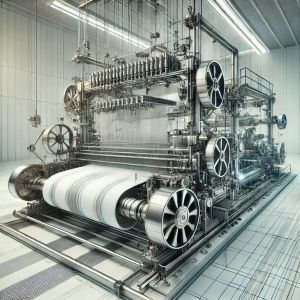

Air Jet Jacquard

Air Jet Jacquard machines combine the precision of Jacquard weaving with the speed of air jet technology. These advanced looms use air jets to insert the weft yarn, enabling rapid and efficient production of fabrics with intricate patterns and designs. Ideal for industrial textile applications, Air Jet Jacquard machines ensure high-quality fabric output with detailed and complex patterns, making them suitable for a wide range of fashion and home textiles.

Air Jet Jacquard, air jet, jacquard air jet Jacquard, weaving, high-speed, intricate patterns, textile machinery, efficiency

-

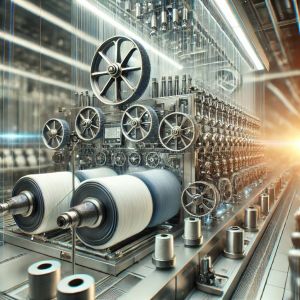

Air Jet Plain

Air Jet Plain looms are designed for high-speed weaving of simple and straightforward fabric patterns. Using air jets to propel the weft yarn, these looms offer rapid and efficient production, making them ideal for large-scale industrial textile manufacturing. Known for their reliability and precision, Air Jet Plain looms are commonly used to produce plain weave fabrics, ensuring consistent quality and high productivity.

Air Jet Plain, air jet air jet plain, weaving, high-speed, simple patterns, textile machinery, efficiency

-

Automatic Length

: The Automatic Length feature is designed for precise and efficient fabric measurement during sewing. It allows for adjustable and consistent lengths, enhancing the accuracy of your stitching projects. Ideal for ensuring uniformity and saving time in both industrial and home sewing environments.

automatic length, sewing, fabric measurement, precision, efficiency, adjustable

-

Bale Packaging

Bale Packaging

Bale Packaging

-

Bleaching Setup

A Bleaching Setup is used in textile and fabric processing to remove natural pigments and prepare materials for dyeing. It involves the use of chemicals and specialized equipment to achieve uniform color removal and enhance fabric whiteness. This setup is crucial for ensuring high-quality results in subsequent dyeing and finishing processes, making it an essential component in textile manufacturing and treatment.

Bleaching Setup, bleaching setup, textile bleaching, chemical treatment, fabric processing, industrial bleaching, dyeing preparation

-

Bobbin Machine

A Bobbin Machine is used to wind thread or yarn onto bobbins, which are essential components in sewing machines. This machine ensures that bobbins are filled with thread evenly and efficiently, providing the necessary supply for sewing operations. It is crucial for maintaining a consistent thread feed and minimizing interruptions during sewing processes. Bobbin machines are commonly used in industrial settings and garment manufacturing to streamline thread preparation and enhance overall productivity.

Bobbin Machine, bobbin machine, bobbin winding, textile machinery, yarn management, sewing machine accessory, industrial bobbin

-

Boiler Machine

Boiler Machine A Boiler Machine is designed to generate steam for heating and powering various industrial processes. It operates under high pressure and efficiently converts energy into heat, essential for processes such as fabric steaming, sterilization, and machinery operation. Ideal for industrial settings requiring reliable and consistent steam production.

boiler machine, steam generation, heating, industrial, efficiency, pressure

-

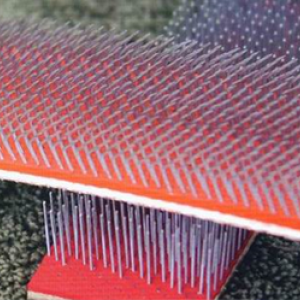

Brushing / Raising Finish

Brushing or Raising Finish is a textile finishing process used to enhance the texture and appearance of fabrics. During this process, the fabric's surface is brushed or raised to create a soft, velvety texture and increase its warmth and comfort. This finish is commonly applied to materials like wool, cotton, and synthetic fabrics to improve their tactile properties and aesthetic appeal, making them more suitable for applications like apparel and home textiles.

Brushing, Raising Finish, brushing finish, raising finish, fabric finishing, textile processing, fabric texture, surface treatment

-

Cad/cam

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) are integrated technologies used in the design and manufacturing process. CAD software allows for detailed digital design and modeling of products, while CAM software translates these designs into precise manufacturing instructions for machinery. Together, CAD and CAM streamline the design-to-production workflow, improving accuracy, efficiency, and productivity in various industries, including textiles, engineering, and automotive. This integration supports complex designs and automates production processes, enhancing overall product quality and reducing time-to-market.

Cad/cam. CAD, CAM, computer-aided design, computer-aided manufacturing, design software, manufacturing technology, digital design

-

Continuous Bleaching

Continuous Bleaching is a method used in textile processing to uniformly bleach large quantities of fabric in a continuous flow. This process involves the use of chemicals and specialized equipment to remove natural pigments and prepare fabrics for subsequent dyeing or finishing. Continuous bleaching is valued for its efficiency and ability to produce consistent results, making it ideal for large-scale textile production and ensuring high-quality standards across extensive fabric runs.

Continuous Bleaching, bleaching, continuous bleaching, textile bleaching, fabric treatment, bleaching process, industrial bleaching, continuous process

-

Covering Machine

A Covering Machine is used to apply protective or decorative coverings to various products or materials. In the textile industry, it is often employed to cover components like spools, rolls, or other fabric items with protective layers or to apply decorative finishes. The machine ensures that coverings are applied evenly and securely, enhancing the durability, appearance, or functionality of the items being covered. Covering machines are crucial for maintaining product quality and extending the lifespan of materials and components.

Covering Machine, covering machine, textile covering, fabric covering, protective coverings, industrial machinery, material handling

-

Cutting Machinery

Cutting Machinery is vital in textile manufacturing, designed for precise and efficient cutting of fabrics in various shapes and sizes. These machines handle large volumes and multiple layers of material, ensuring consistent and accurate cuts. Essential for speeding up production and enhancing the quality of finished products in industrial settings.

cutting machinery, fabric cutting, industrial, precision, efficiency, textile manufacturing

-

Digital and Laser Cutting Machinery

Digital and Laser Cutting Machinery uses advanced technologies to achieve precise and efficient cutting of materials. Digital cutting machines often employ automated controls for accurate cuts based on digital patterns, while laser cutting machines use focused laser beams to cut through various materials with high precision. These technologies are widely used in textiles, manufacturing, and various industries for their ability to produce intricate designs, reduce material waste, and enhance overall production efficiency.

Digital and Laser Cutting Machinery, cutting machine, laser, digital cutting, laser cutting, automatic cutting, auto cutting, cutting machine, digital cutting, laser cutting, cutting machinery, textile cutting, precision cutting, automated cutting

-

Drying Setup

Drying systems. A Drying Setup is used in various industries to remove moisture from materials, such as textiles or chemicals, ensuring they reach the desired dryness level. It includes specialized equipment and techniques designed to efficiently dry large quantities of products while maintaining their quality. This setup is essential in processes like textile finishing and food processing, where proper drying is crucial for achieving optimal product performance and longevity.

Drying Setup, drying, drying setup, industrial drying, textile drying, moisture removal, drying equipment, fabric processing, Drying systems

-

Drying Setup-Can Dryers

Can Dryers are designed for efficient drying of fabrics in an industrial setting. This setup utilizes can-shaped containers or cylinders to ensure consistent and uniform drying. Ideal for high-volume textile production, Can Dryers offer reliable performance and help maintain fabric quality while optimizing the drying process.

Drying Setup, Can Dryers drying setup, can dryers, fabric drying, industrial, efficient, consistent

-

Drying Setup-Conveyor Dryer

A Conveyor Dryer is designed for continuous drying of fabrics in an industrial setting. The setup features a conveyor belt that moves materials through a drying chamber, ensuring consistent and efficient drying. It is ideal for handling large volumes of fabric, providing reliable performance and maintaining high fabric quality throughout the drying process.

drying Setup, Conveyor Dryer drying setup, conveyor dryer, fabric drying, industrial, continuous, efficient

-

Drying Setup-Steam Tumbler

The Steam Tumbler Drying Setup uses steam to assist in drying fabrics, providing an efficient and effective method for large-scale textile production. This setup enhances the drying process by utilizing steam to maintain fabric quality and reduce drying time. Ideal for achieving consistent results and optimizing production efficiency in industrial settings.

Drying Setup, Steam Tumbler drying setup, steam tumbler, fabric drying, industrial, efficient, steam-assisted

-

Drying Setup-Tumble Dryer

A Tumble Dryer is a type of drying machine used to remove moisture from fabrics and textiles through a rotating drum that circulates warm air. It is commonly used in both industrial and household settings to efficiently dry large volumes of textiles, such as clothes and towels. The tumbler's rotating action ensures even drying, reducing wrinkles and maintaining fabric quality. This setup is crucial for streamlining the drying process and improving overall efficiency in textile processing.

Drying Setup,Tumble Dryer, tumble dryer, drying setup, fabric drying, industrial dryer, textile drying, moisture removal

-

Drying Setup: Continuous Anglada Tumbler

The Continuous Anglada Tumbler is a drying setup designed for efficient, continuous drying of textiles. It features advanced temperature control and airflow systems to ensure uniform drying, making it ideal for high-volume textile production. This setup helps maintain fabric quality while optimizing the drying process.

Drying Setup, Continuous Anglada Tumbler drying setup, Anglada tumbler, continuous drying, textile, efficiency, temperature control

-

Drying Setup: Continuous Tumbler

The Continuous Tumbler Drying Setup is engineered for the efficient drying of fabrics in a continuous process. It ensures consistent results with effective temperature and airflow control, making it suitable for large-scale textile operations. This setup enhances productivity and fabric quality while reducing drying time.

Drying Setup, Continuous Tumbler drying setup, continuous tumbler, fabric drying, industrial, efficiency, consistent results

-

Dyeing Setup- Air and Liquid Multi Flow Dyeing

The Air and Liquid Multi Flow Dyeing Setup is an advanced dyeing technology designed to enhance the efficiency and uniformity of fabric dyeing. It combines air and liquid flow systems to ensure even dye distribution and optimal color absorption. This setup is used to achieve high-quality dyeing results for various fabric types, providing consistent and vibrant colors while minimizing water and chemical usage. It is ideal for large-scale textile operations seeking to improve dyeing performance and reduce environmental impact.

Dyeing Setup, Air and Liquid Multi Flow Dyeing, air dyeing, liquid dyeing, multi flow dyeing, textile dyeing, dyeing technology, fabric coloration

-

Dyeing Setup- Atmospherinc Dying

: Atmospheric Dyeing involves a setup that maintains a controlled environment for dyeing textiles at atmospheric pressure. This method ensures precise color application and consistent results by managing factors like temperature and humidity. Ideal for achieving high-quality, vibrant colors, it is commonly used in industrial settings to enhance fabric dyeing processes.

Dyeing, Fabric Dyeing, Dyeing Setup, Atmospheric Dying dyeing setup, atmospheric dyeing, textile dyeing, controlled environment, precision, fabric quality

-

Dyeing Setup- High Temp Jet Dyeing Machine

The High Temp Jet Dyeing Machine is designed for dyeing textiles at elevated temperatures, allowing for deep and vibrant color penetration. This setup is highly efficient and ideal for processing a wide range of fabrics, ensuring consistent dyeing results. Commonly used in industrial applications, it enhances productivity while maintaining the quality and durability of the dyed fabric.

Dyeing Setup, High Temp Jet Dyeing Machine, Dyeing, Fabric Dyeing dyeing setup, high temp jet dyeing, textile dyeing, high temperature, efficiency, fabric quality

-

Dyeing Setup- J-box

The J-Box is an essential component in dyeing setups, designed for temporary fabric storage during continuous dyeing processes. It allows for controlled relaxation and even distribution of fabric as it moves through different stages of dyeing. Ideal for industrial applications, the J-Box ensures smooth workflow, consistent dye penetration, and prevents fabric tension issues during processing.

Dyeing Setup, J-box, fabric dyeing, dyeing dyeing setup, J-box, textile processing, fabric storage, continuous dyeing, industrial

-

Dyeing Setup-Close Winch Dyeing

Yarn Dyeing Setup is specifically designed for applying color to yarns before they are woven or knitted into fabrics. This process ensures precise and consistent color application, enhancing the quality and appearance of the final textile product. Ideal for industrial operations, yarn dyeing allows for creative patterns and color effects while maintaining high standards of colorfastness and durability.

Dyeing Setup, Close Winch Dyeing, fabric dyeing, dyeing dyeing setup, yarn dyeing, textile dyeing, precision, color consistency, industrial

-

Dyeing Setup-Continuous Dyeing

Continuous Dyeing Setup is designed for the efficient and uniform dyeing of textiles in a continuous process. This setup allows for the uninterrupted application of dye to large volumes of fabric, ensuring consistent color and high production efficiency. Ideal for industrial textile operations, it improves workflow and reduces downtime while maintaining fabric quality.

Dyeing Setup, Continuous Dyeing, Dyeing, Fabric Dyeing dyeing setup, continuous dyeing, textile processing, efficiency, uniformity, industrial

-

Dyeing Setup-German Dyeing Machines

Dyeing Setup-German Dyeing Machines German Dyeing Machines are renowned for their precision and high-quality performance in textile dyeing. Designed for industrial use, these machines offer advanced technology and efficiency, ensuring consistent and vibrant color results. Ideal for large-scale dyeing operations, they enhance productivity and maintain excellent fabric quality.

Dyeing, dyeing setup, German Dyeing Machines dyeing setup, German dyeing machines, textile dyeing, precision, high-quality, industrial

-

Dyeing Setup-Sclavos Fabric Dyeing

Sclavos Fabric Dyeing systems are designed for precise and high-quality textile dyeing. Known for their efficiency and advanced technology, these setups ensure consistent color application and excellent fabric quality. Ideal for industrial applications, Sclavos machines enhance productivity while delivering vibrant and accurate dye results.

Dyeing Setup, Sclavosyeing, Fabric Dyeing Fabric Dyeing, dyeing setup, Sclavos fabric dyeing, textile dyeing, precision, high-quality, efficiency

-

Dyeing Setup-Soft Flow Dyeing

Soft Flow Dyeing Setup is designed for the gentle dyeing of delicate and lightweight fabrics. This process uses a continuous flow of dye liquor to ensure even color distribution while minimizing fabric stress and damage. Ideal for producing high-quality, vibrant textiles, this setup is commonly used in industrial applications where fabric care and quality are paramount.

Dyeing Setup, Soft Flow Dyeing, fabric dyeing, dyeing dyeing setup, soft flow dyeing, textile dyeing, gentle process, fabric care, high-quality

-

Dyeing Setup-Yarn Dyeing

Yarn Dyeing Setup is specifically designed for applying color to yarns before they are woven or knitted into fabrics. This process ensures precise and consistent color application, enhancing the quality and appearance of the final textile product. Ideal for industrial operations, yarn dyeing allows for creative patterns and color effects while maintaining high standards of colorfastness and durability.

Dyeing Setup,Yarn Dyeing, fabric dyeing, dyeing dyeing setup, yarn dyeing, textile dyeing, precision, color consistency, industrial

-

Embroidery Machine

An Embroidery Machine is a specialized device designed for adding intricate and decorative designs to fabrics. It uses automated stitching technology to create patterns, logos, and embellishments with high precision and consistency. Ideal for garment customization, promotional items, and textile arts, this machine enhances the visual appeal and value of products by producing detailed and professional-quality embroidery.

Embroidery Machine, embroidery, embroidery machine, textile embroidery, decorative stitching, garment customization, automated embroidery, embroidery technology

-

Fabric Grading Machine

A Fabric Grading Machine is designed to evaluate and classify fabrics based on quality and characteristics. It assesses attributes such as defects, texture, and consistency to ensure fabrics meet specified standards. This machine is vital for quality control in textile manufacturing, helping to sort and grade fabric rolls efficiently and accurately, which enhances overall product quality and reduces waste.

Fabric Grading Machine, grading machine, grading, fabric grading, fabric grading machine, textile quality control, fabric assessment, grading system, textile machinery, quality evaluation

-

Fabrics Inspection Machine

A Fabrics Inspection Machine is a crucial tool in the textile industry, designed for the thorough examination of fabric rolls. It identifies defects, inconsistencies, and color variations to ensure high-quality standards are met before the fabric is processed further. This machine enhances quality control by providing precise and efficient inspection, helping manufacturers maintain consistent product quality.

Fabrics inspection machine, fabrics inspection machine, textile quality control, fabric inspection, defect detection, textile machinery, quality assurance

-

Finishing Machines

Finishing Machines are used in the textile industry to enhance the appearance, feel, and performance of fabrics and garments after they have been woven or knitted. These machines perform various processes such as smoothing, pressing, coating, or adding special effects to the fabric. Finishing treatments improve fabric properties like softness, durability, and wrinkle resistance, and can include processes such as calendaring, heat setting, and chemical finishing. These machines are essential for achieving the desired quality and functionality in final textile products.

Finishing Machines, finishing, finishing machines, textile finishing, fabric treatment, surface finishing, garment finishing, final processing

-

Fleece

Fleece is a soft, warm fabric known for its insulating properties and versatility. Typically made from synthetic fibers like polyester, it is commonly used in outdoor clothing, blankets, and other apparel. Its lightweight and breathable nature make it ideal for providing warmth and comfort in various settings.

Fleecefleece, fabric, soft, warm, insulating, versatile

-

Full Automatic Cotton terry face towel sewing machine

The Full Automatic Cotton Terry Face Towel Sewing Machine is an advanced textile machine designed for the efficient production of cotton terry face towels. It automates the sewing process, ensuring precise and consistent stitching, which increases productivity and maintains high-quality standards in towel manufacturing. This machine is ideal for large-scale textile operations seeking to optimize production efficiency and reduce manual labor.

Full Automatic Cotton terry face towel sewing machine, TPET, automatic sewing machine, cotton terry, face towel, textile machinery, towel production, automated stitching

-

Fusing Machine

A Fusing Machine is essential in the garment industry for bonding fabric layers using heat and pressure. It ensures a secure and durable attachment of interlinings, enhancing the quality and appearance of finished garments. This machine is widely used in textile manufacturing for precision and efficiency in fabric fusing processes.

Fusing machine, Fusing, fusing machine, garment industry, fabric bonding, heat press, textile machinery, fusing technology

-

Hemming-Auto Hemming Setup

An Auto Hemming Setup refers to an automated system designed for efficient and precise hemming of garments or textiles. This setup integrates advanced technology to perform hemming tasks with minimal manual intervention, ensuring consistent quality and faster production speeds. It is ideal for high-volume manufacturing environments where efficiency and accuracy are crucial. The auto hemming setup enhances productivity, reduces labor costs, and delivers high-quality hem finishes on a variety of fabrics.

Hemming, Auto Hemming Setup, auto hemming setup, automated hemming, textile machinery, garment finishing, industrial sewing, hem automation

-

Hemming-Bando Long Hemming Machines

Bando Long Hemming Machines are specialized sewing machines designed for the efficient and precise hemming of long or large fabric pieces. These machines provide a consistent, high-quality hem finish on garments or textiles, accommodating longer lengths of fabric with ease. Ideal for industrial and garment manufacturing settings, Bando long hemming machines ensure accurate hemming, enhance productivity, and deliver a professional appearance to finished products. They are essential for producing clean and durable hems on various types of garments and fabrics.

Hemming, Bando Long Hemming Machines, Bando long hemming machines, long hemming, textile machinery, garment hemming, industrial sewing, hem finishing

-

Hemming-Barudan Hemming Machine

The Barudan Hemming Machine is a high-performance machine designed for precise and efficient hemming of garments and textiles. Known for its reliability and advanced features, this machine is used to create professional-quality hems with consistent stitching on various fabric types. It is particularly valued in industrial settings for its ability to handle large volumes and deliver clean, durable hem finishes, enhancing the overall quality and appearance of the final products.

Hemming, Barudan Hemming Machine, Barudan hemming machine, hemming technology, textile machinery, garment hemming, industrial sewing, hem finishing

-

Hemming-Short Hem Machine

The Short Hem Machine is specialized for hemming, providing a clean and professional finish to garment edges. Designed for precision, this machine is ideal for creating short hems, ensuring garments have a neat and durable edge. Perfect for both industrial and home use.

hemming, short hem machine, sewing, finishing, garment, edge

-

In House Power Generation

In-House Power Generation refers to the process of producing electricity within a facility, rather than relying on external power sources. This setup often includes technologies such as generators, turbines, or renewable energy systems like solar panels or wind turbines. It provides a reliable and self-sufficient power supply, ensuring continuity of operations and enhancing energy security. In-house power generation is beneficial for managing energy costs, supporting critical systems, and achieving greater control over power availability.

In House Power Generation, in-house power generation, on-site power, energy solutions, power systems, backup power, energy management

-

Inspecting

Inspecting involves the systematic examination of products or materials to assess their quality and identify any defects or inconsistencies. This process is critical in various industries, including manufacturing and textiles, to ensure that products meet specified standards and are free from flaws. Effective inspecting helps maintain high quality, enhance product reliability, and ensure customer satisfaction by identifying and addressing issues before products reach the market.

Inspecting, quality control, inspecting, quality control, inspection process, product assessment, defect detection, quality assurance

-

Knitting Setup

A Knitting Setup involves configuring machines for fabric production, ensuring precision and consistency in creating various textile textures and patterns. This setup accommodates different types of yarn and knitting techniques, making it suitable for producing a wide range of fabrics. Essential for achieving high-quality and reliable results in both industrial and home knitting projects.

Knitting Setup, knitting knitting setup, fabric production, precision, machine configuration, yarn, texture

-

Knitting Setup- 4 Track Single Jersey

Knitting Setup- 4 Track Single Jersey, circular knitting machineThe 4 Track Single Jersey Knitting Setup is designed for producing smooth and versatile single jersey fabrics. This setup features four tracks of knitting needles, enabling the creation of uniform, flexible, and lightweight fabrics ideal for various garments and textiles. It ensures consistent quality and is commonly used in both fashion and sportswear production.

Knitting Setup, 4 Track Single Jersey, knitting knitting setup, 4 track, single jersey, fabric, smooth, versatile

-

Knitting Setup: Terrot Machines

terrot Machines are renowned for their precision and efficiency in knitting setup. These machines are used to produce high-quality fabrics with consistent patterns and textures. Ideal for industrial applications, Terrot machines support a wide range of knitting styles and fabric types, ensuring durability and performance in fabric production.

Knitting Setup, Terrot Machines, knitting knitting setup, Terrot machines, high-quality knitting, fabric production, precision, industrial

-

Lamination Finish

Lamination Finish involves applying a protective coating to surfaces to enhance durability and appearance. This process provides a glossy or matte finish that guards against wear and tear, moisture, and other environmental factors. Commonly used in industrial applications and for finishing printed materials, it ensures a high-quality, long-lasting surface.

Lamination Finishlamination finish, surface protection, durability, coating, industrial, glossy

-

Looms- Fluid-jet Looms

Fluid-Jet Looms are advanced weaving machines that use either air or water jets to propel the weft yarn through the warp at high speeds. These looms are known for their efficiency and ability to produce lightweight, high-quality fabrics. Ideal for industrial textile production, fluid-jet looms offer precise control and are particularly suited for weaving fine and delicate materials with consistent performance and minimal fabric stress.

Looms, Fluid-jet Looms looms, fluid-jet looms, weaving, high-speed, air jet, water jet, textile machinery

-

Looms- Needle Looms

Needle Looms are specialized weaving machines designed for producing narrow fabrics such as tapes, ribbons, and webbings. These looms use needles to insert the weft yarn, ensuring precise and efficient weaving at high speeds. Ideal for industrial applications, needle looms provide consistent quality and are essential in the production of various narrow textile products, including those used in fashion, upholstery, and safety equipment.

Looms, Needle Looms looms, needle looms, narrow fabric weaving, precision, high-speed, textile machinery

-

Looms- Rapier Looms

Rapier Looms are versatile weaving machines known for their ability to produce a wide range of fabrics with varying complexities. These looms use a rapier system to insert the weft yarn into the warp, allowing for precise and efficient weaving at high speeds. Ideal for both simple and intricate patterns, rapier looms are commonly used in industrial textile production, offering reliability and flexibility in fabric manufacturing.

looms, rapier looms, weaving, high-speed, versatile, textile machinery

-

Looms- Semi Automatic Terry Looms

Semi-Automatic Terry Looms are specialized weaving machines designed for producing terry fabrics, commonly used in towel manufacturing. These looms automate certain aspects of the weaving process while allowing manual control for specific adjustments. Ideal for industrial textile production, they offer a balance of efficiency and precision, ensuring high-quality terry fabric with consistent loop formation and texture.

Looms, Semi Automatic Terry Looms, terry looms, semi-automatic terry looms, towel weaving, fabric production, efficiency, textile machinery

-

Looms-Vamatex Looms

Vamatex Looms are advanced weaving machines known for their versatility and high-speed performance. Designed to handle a wide range of fabric types, these looms are equipped with cutting-edge technology to ensure precise and efficient weaving. Ideal for industrial textile production, Vamatex looms offer reliability and flexibility, making them suitable for both simple and complex fabric designs.

Looms-Vamatex Looms looms, Vamatex looms, weaving, high-speed, versatile, textile machinery, advanced technology

-

Metal Detector Machine

A Metal Detector Machine is a vital tool used in security and industrial applications to detect and identify metal objects. It ensures safety and compliance by screening for metal contaminants in products or preventing unauthorized items from entering secure areas. The machine is highly sensitive and reliable, making it an essential component in quality control and security operations.

Metal detector machine, metal detector, security equipment, detection machine, industrial safety, metal detection, screening technology

-

MIC Technology Setup

Micronaire is a key measurement in cotton technology, indicating the quality and fineness of cotton fibers. It plays a crucial role in the textile industry by determining the suitability of cotton for various applications, impacting the feel, strength, and dyeing properties of the final fabric. MIC Technology Setup involves the installation and configuration of advanced technology solutions designed to enhance operational efficiency and management. This setup focuses on implementing scalable and innovative technologies that streamline processes and optimize performance. With a focus on cutting-edge solutions, MIC Technology Setup ensures seamless integration and effective management of technological resources to meet modern business needs.

micronaire in cotton,air permeabilty,compressed cotton fibers,fiber,fineness,maturity, micronaire, cotton technology, fiber quality, cotton measurement, textile industry, cotton processing, MIC technology setup, advanced, installation, management, efficie

-

Packaging

Packaging involves the process of enclosing and protecting products for distribution, storage, and sale. It includes designing and using materials to ensure products are securely contained, preserved, and presented attractively. Effective packaging solutions are essential for maintaining product integrity, facilitating handling and transport, and enhancing brand presentation. Packaging can vary widely depending on the product type, industry requirements, and logistical considerations.

Packaging, boxing, packaging, industrial packaging, product packaging, packaging solutions, material handling, packaging design

-

Pattern Grading

Pattern Grading is the process of creating a range of sizes for a garment pattern based on a base size. It involves scaling the original pattern up or down to produce different size variations while maintaining the proportions and fit of the design. This process is essential in fashion design and garment manufacturing to ensure that clothing fits well across various sizes and meets industry standards. Pattern grading helps in producing accurate and consistent patterns for mass production, ensuring that garments fit correctly and look professional.

Pattern Grading, grading, pattern grading, garment sizing, pattern adjustment, fashion design, textile pattern, size scaling

-

Plain Kier

A Plain Kier is a large industrial vessel used in the textile industry for boiling and scouring fabrics. This process removes impurities, natural oils, and waxes from the fabric, preparing it for dyeing or further processing. Known for its efficiency in fabric preparation, the Plain Kier is essential in ensuring the quality and cleanliness of textiles before they undergo additional treatments.

Plain Kier plain kier, textile processing, fabric boiling, scouring, industrial, fabric preparation

-

Power Looms Jacquard

Jacquard Power Looms are specialized weaving machines equipped with a Jacquard mechanism, enabling the creation of intricate and complex fabric patterns. These looms operate at high speeds and offer precise control over individual warp threads, making them ideal for producing detailed designs in textiles. Widely used in industrial applications, Jacquard Power Looms combine efficiency with the ability to create high-quality, ornate fabrics.

Power Looms Jacquard power looms, Jacquard weaving, intricate patterns, textile machinery, high-speed, precision

-

Power Looms Jacquard Terry

Jacquard Terry Power Looms are advanced weaving machines designed to produce terry fabrics with intricate patterns and designs. Utilizing the Jacquard mechanism, these looms allow for precise control over individual warp threads, enabling the creation of complex and detailed patterns in terry cloth. Ideal for towel manufacturing, these looms combine efficiency with high-quality fabric production, making them a staple in the textile industry.

Power Looms, Jacquard, Terry power looms, Jacquard terry, towel weaving, intricate patterns, textile machinery, efficiency power looms, Jacquard terry, towel weaving, intricate patterns, textile machinery, efficiency

-

Power Looms Plain

Power Looms for Plain Weaving are designed for the efficient production of plain weave fabrics. These looms operate at high speeds, offering reliable and consistent performance in industrial textile manufacturing. Ideal for producing basic and uniform fabric patterns, plain power looms ensure high productivity while maintaining fabric quality, making them a staple in large-scale textile operations.

Power Looms Plain power looms, plain weaving, textile machinery, high-speed, efficient, industrial production

-

Printing Machine

A Printing Machine is designed for applying designs and patterns onto various materials, including textiles. It offers high-speed operation and precision, making it suitable for both large-scale industrial applications and smaller production runs. With features that accommodate different printing techniques and materials, this machine ensures consistent and high-quality prints across a range of products.

Printing Machine printing machine, textile printing, high-speed, precision, versatility, industrial

-

Printing Rotary Machine

A Printing Rotary Machine is designed for high-speed, continuous printing on textiles and other materials. Utilizing a rotary printing mechanism, it offers precision and efficiency, making it ideal for large-scale production. This machine ensures consistent print quality and is commonly used in the textile industry for producing detailed and vibrant designs.

Printing Rotary Machine, printingprinting rotary machine, rotary printing, high-speed, textile printing, precision, efficiency

-

Range Cutting

Range Cutting refers to a cutting technique designed for handling multiple layers of fabric simultaneously with precision and efficiency. Ideal for industrial applications, this method ensures consistent cuts across a wide range of materials, speeding up the production process and improving overall accuracy.

range cutting, fabric cutting, precision, multiple layers, efficient, industrial

-

Reactive And Digital Printing Latest Machinery.

The latest machinery for Reactive and Digital Printing combines advanced technology to deliver high-resolution and vibrant prints on textiles. Reactive printing involves using dyes that chemically bond with fabric fibers, while digital printing offers precise, on-demand printing capabilities. This state-of-the-art equipment enhances print quality, efficiency, and versatility, making it suitable for a wide range of textile applications.

Reactive, Digital Printing, Latest Machinery, Digital Printing Latest Machinery.reactive printing, digital printing, latest machinery, textile printing, high-resolution, advanced technology

-

Rotor Machines

Rotor Machines are used in the spinning process to produce yarns from fiber. They operate at high speeds and use a rotor mechanism to spin and twist fibers into yarns efficiently. These machines are known for their ability to handle various fiber types and provide consistent yarn quality. Ideal for large-scale textile production, rotor machines enhance productivity and optimize yarn production processes.

Rotor Machines rotor machines, spinning, yarn production, high-speed, efficiency, textile machinery

-

Shearing Machines

Shearing Machines are used for trimming and cutting fabrics with precision. Designed for industrial use, these machines efficiently handle large volumes of material, ensuring clean and accurate cuts. They are essential in textile production for creating uniform fabric pieces and improving the overall quality of finished products.

Shearing Machines shearing machines, fabric trimming, cutting, precision, industrial, efficiency

-

Shuttleless - Smit Shuttleless Looms

: Smit Shuttleless Looms are advanced weaving machines designed to operate without traditional shuttles, enabling high-speed and efficient fabric production. These looms use various mechanisms, such as air jets or rapier systems, to insert the weft yarn into the warp, improving productivity and reducing fabric defects. Ideal for industrial textile manufacturing, Smit shuttleless looms offer precision and versatility for producing a wide range of woven fabrics.

Shuttleless , Smit Shuttleless Loom shuttleless, Smit shuttleless looms, weaving, high-speed, efficiency, advanced technology

-

Shuttleless Dobby Looms

Shuttleless Dobby Looms are advanced weaving machines that operate without the need for a shuttle, using a dobby mechanism to control the pattern of the weave. This technology allows for higher weaving speeds and greater versatility in fabric design, enabling the production of intricate patterns and complex weaves with increased efficiency. These looms are essential in modern textile manufacturing, offering improved performance and precision in fabric production.

Shuttleless Dobby Looms, dobby looms, Shuttle-less Dobby Shuttle-less Dobby LoomsLooms, shuttleless dobby looms, weaving technology, textile machinery, fabric production, advanced looms, dobby weaving

-

Shuttleless Jacquard Loom

The Shuttleless Jacquard Loom integrates Jacquard technology with shuttleless weaving mechanisms, such as air jet or rapier systems. This combination allows for the creation of intricate and detailed patterns while maintaining high-speed and efficient fabric production. Ideal for industrial textile manufacturing, it offers precise control over warp threads and enhances productivity, making it suitable for producing complex and high-quality woven fabrics.

Shuttleless Jacquard Loom shuttleless Jacquard loom, weaving, intricate patterns, high-speed, textile machinery, efficiency

-

Shuttleless Plain Looms

Shuttleless Plain Looms are designed for efficient and high-speed weaving without the use of traditional shuttles. They use advanced mechanisms, such as air jets, rapier systems, or grippers, to insert the weft yarn into the warp, enabling continuous and precise fabric production. Ideal for industrial applications, these looms offer improved productivity, reduced fabric defects, and versatility for creating plain weave fabrics.

Shuttleless Plain Looms shuttleless, plain looms, weaving, high-speed, efficiency, industrial

-

Shuttleless Vamatex Loom

The Shuttleless Vamatex Loom is a high-performance weaving machine designed to operate without traditional shuttles, utilizing advanced technologies like rapier or air jet systems for efficient fabric production. Known for its high-speed operation and precision, the Vamatex loom enhances productivity and fabric quality, making it suitable for industrial textile manufacturing. It is versatile, handling a variety of fabric types and weaves with consistency and reliability.

Shuttleless Vamatex Loom shuttleless, Vamatex loom, weaving, high-speed, precision, industrial

-

Sizing Machine

A Sizing Machine is essential in textile manufacturing, designed to coat warp yarns with a protective layer before weaving. This process enhances yarn strength, reduces breakage, and improves smoothness, ensuring a higher quality fabric during the weaving process. Ideal for optimizing efficiency and fabric durability in industrial settings.

sizing machine, textile, fabric preparation, warp yarn, strength, smoothness

-

Spindles of Ring Yarn

Spindles of Ring Yarn refer to the components of a ring spinning system used to produce yarn. These spindles are integral to the ring spinning process, where fibers are twisted into yarns by rotating spindles. The quality and efficiency of the yarn produced depend significantly on the performance of these spindles, which are designed to handle various fiber types and yarn counts. Ring spinning is known for its ability to produce high-quality, strong yarns suitable for a wide range of textile applications.

Spindles of Ring Yarn, spindles, ring yarn, spinning technology, yarn production, textile machinery, ring spinning

-

Spinning Machine

A Spinning Machine is used in the textile industry to convert fibers into yarns. It processes raw fibers, such as cotton or wool, through various stages of drafting, twisting, and winding to produce yarns of different thicknesses and strengths. Spinning machines are essential for creating the foundational material for fabrics and textiles, ensuring consistency and quality in yarn production.

Spinning Machine, winding machine, spinning machine, yarn production, textile machinery, fiber spinning, spinning technology, textile manufacturing

-

Spinning- Murata Air Jet Spinning

The Murata Air Jet Spinning system is a high-speed yarn production method known for its efficiency and precision. It uses air jets to spin fibers into yarn, providing a high-quality finish and consistent results. Ideal for industrial applications, this technology enhances productivity and yarn strength.

Spinning, Murata Air Jet SpinningMurata Air Jet Spinning, yarn production, high-speed, efficiency, precision

-

Stitching Setup

A Stitching Setup involves configuring sewing machines for specific tasks, ensuring optimal performance and precision. Whether for basic or complex stitching, this setup allows customization to handle various fabrics and stitching patterns. Essential for achieving high-quality results in both industrial and home sewing projects.

stitching setup, sewing, machine setup, fabric, precision, customization

-

Stitching Setup- Automatic/ Computerized Sewing

The Automatic/Computerized Sewing Setup is a cutting-edge system designed for precision and efficiency in sewing. It utilizes advanced technology to automate stitching processes, allowing for programmable patterns and consistent results. Ideal for both industrial and home use, this setup enhances productivity and ensures high-quality finishes across various fabrics and designs.

Stitching Setup, Automatic sewing, Computerized Sewing, automatic stitching, computerized stitching stitching setup, automatic sewing, computerized sewing, precision, efficiency, programmable, advanced technology

-

Stitching Setup- Bar Tack

A Bar Tack Stitching Setup is used to reinforce areas of garments and textiles that experience high stress, such as pocket openings, belt loops, and seam intersections. This setup typically involves a bar tack machine that creates a series of tight, parallel stitches to provide additional strength and durability. Bar tacking ensures that these critical areas are securely stitched, preventing wear and tear and enhancing the overall quality and longevity of the finished product. This setup is crucial for industrial garment manufacturing, where reinforcement is essential for product performance and durability.

Stitching Setup, Bar Tack, bar tack, bar tack machine, stitching setup, garment reinforcement, textile machinery, stitching reinforcement

-

Stitching Setup- Button Sew

A Button Sew Setup is designed for attaching buttons to garments with precision and efficiency. This setup typically includes specialized machines that automate the button-sewing process, ensuring consistent placement and secure attachment. It is commonly used in garment manufacturing to streamline the finishing process, reduce manual labor, and enhance the overall quality of the final product. Button sew machines are essential for producing well-finished garments with professionally attached buttons, contributing to both functionality and aesthetic appeal.

Stitching Setup, Button Sew, button sew, button sewing machine, stitching setup, garment finishing, textile machinery, button attachment

-

Stitching Setup- Buttonhole

A Buttonhole Stitching Setup is specialized for creating buttonholes in garments and textiles. This setup typically includes machines designed to accurately cut and stitch buttonholes with consistent dimensions and finishing. It automates the process, ensuring precise placement and secure stitching of buttonholes, which is crucial for functionality and aesthetics in garments. Buttonhole machines are essential for achieving high-quality, durable buttonholes in large-scale production environments, improving efficiency and product quality.

Stitching Setup, Buttonhole, buttonhole stitching, buttonhole machine, stitching setup, garment finishing, textile machinery, buttonhole creation

-

Stitching Setup- Double Needle

The Double Needle Stitching Setup utilizes two needles to create parallel rows of stitches, enhancing both durability and visual appeal. Ideal for sewing tasks that require strong, decorative seams, this setup is commonly used in garment construction and industrial sewing. It ensures precision and consistent results across various fabrics.

stitching setup, double needle, sewing, parallel stitches, durability, precision

-

Stitching Setup- Elastic Sewing Machine

An Elastic Sewing Machine is designed for sewing elastic materials into garments or textiles. This specialized machine handles stretch fabrics and elastic components with precision, providing the necessary flexibility and durability for products such as activewear, undergarments, and fitted garments. It ensures accurate stitching of elastic bands and seams, maintaining fabric elasticity and enhancing comfort and fit. This setup is crucial for producing high-quality, stretchy garments and ensuring reliable performance in garment construction.

Stitching Setup, Elastic Sewing Machine, elastic sewing machine, stitching setup, elastic fabric, garment sewing, textile machinery, stretch sewing

-

Stitching Setup- Embroidered Stitching

An Embroidered Stitching Setup involves specialized equipment and techniques for adding decorative patterns and designs to fabrics. This setup typically includes embroidery machines capable of stitching intricate designs with precision and consistency. It is used in the garment industry to enhance the visual appeal of clothing and textiles, providing a variety of decorative effects such as logos, motifs, and elaborate patterns. This setup combines artistic design with technical stitching skills to create unique and high-quality embroidered products.

Stitching Setup, Embroidered Stitching, embroidered stitching, embroidery setup, stitching machine, textile embroidery, decorative stitching, garment embellishment, Embroidery Stitching Machine, sewing

-

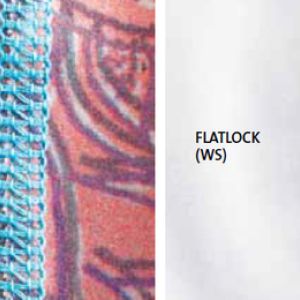

Stitching Setup- Flat Lock

A Flat Lock Stitching Setup is used for creating flat seams in garments and textiles, which are essential for achieving a smooth and comfortable finish. This setup involves a flat lock machine that joins fabric layers with a stitch that lies flat, reducing bulk and preventing irritation. It is commonly used in activewear, sportswear, and other garments where a seamless finish is desired. Flat lock stitching provides durability and a clean appearance, making it ideal for both functional and aesthetic purposes in garment manufacturing.

Stitching Setup, Flat Lock, flat lock stitching, flat lock machine, stitching setup, seam construction, garment finishing, textile machinery

-

Stitching Setup- Interlock Machine

The Interlock Machine is designed for constructing durable, flexible seams on knit fabrics. It creates a lockstitch with interlocking loops, providing strength and stretchability, making it ideal for garments that require both durability and comfort. This setup ensures consistent, high-quality seams and is commonly used in garment manufacturing and textile production.

Stitching Setup, Interlock Machinestitching setup, interlock machine, seam construction, knit fabrics, durability, stretch

-

Stitching Setup- Juki Machines

Juki Machines are renowned for their precision and reliability in stitching setups across various textile and garment manufacturing processes. Juki offers a range of industrial sewing machines designed to handle various stitching tasks, from basic seams to complex decorative patterns. These machines are known for their durability, advanced features, and high performance, making them a popular choice for achieving professional-quality stitching in both small-scale and large-scale production environments. Juki machines help enhance efficiency, accuracy, and overall stitching quality.

Stitching Setup, Juki Machines, Juki machines, stitching setup, industrial sewing, textile machinery, Juki sewing machines, garment stitching

-

Stitching Setup- Multi Needle

A Multi Needle Stitching Setup involves using a sewing machine equipped with multiple needles to create complex and durable stitches on fabrics. This setup allows for simultaneous stitching with several needles, which is ideal for producing decorative patterns, reinforced seams, and detailed embroidery. It is commonly used in industrial settings for efficient and high-quality garment manufacturing, enhancing production speed and providing versatility in stitch patterns and designs. Multi needle machines are essential for tasks requiring precision and multiple thread lines.

Stitching Setup, Multi Needle, multi needle stitching, multi needle sewing machine, textile machinery, garment stitching, industrial sewing, multi-thread sewing

-

Stitching Setup- Overlock Machines

Overlock Machines, also known as sergers, are used for finishing the edges of fabrics to prevent fraying and provide a clean, professional look. These machines sew multiple threads simultaneously, creating a strong, durable seam that encloses the raw edges of the fabric. They are essential for garment construction and textile manufacturing, offering a fast and efficient way to produce high-quality, finished edges on a wide range of fabrics. Overlock machines are particularly useful for sewing knit fabrics and adding decorative stitches.

Stitching Setup, Overlock Machines, overlock machines, stitching setup, serger, edge finishing, seam sewing, textile machinery

-

Stitching Setup- Single Needle

A Single Needle Stitching Setup features a sewing machine that uses a single needle to create precise and durable stitches. This setup is commonly used in garment manufacturing and textile industries for straightforward stitching tasks, including seams, hems, and other basic sewing operations. It is valued for its simplicity, reliability, and ability to produce high-quality stitches on a variety of fabrics.

Stitching Setup, Single Needle, single needle stitching, sewing setup, textile stitching, sewing machine, garment manufacturing, stitch quality

-

Stitching Setup-Lockstitch

The Lockstitch is a popular type of stitching setup known for its durability and precision. Commonly used in industrial sewing machines, it creates strong, secure stitches, making it ideal for a wide range of fabrics and applications.

stitching setup, lockstitch, sewing, durable, precise, industrial sewing

-

Stitching Setup-Straight Stitch

The Straight Stitch is a fundamental stitching setup, known for its simplicity and versatility. It's the most basic and widely used stitch in sewing, creating a straight line of stitches that works well with a variety of fabrics. Ideal for both beginner and advanced sewing projects.

stitching setup, straight stitch, sewing, basic stitch, versatile, fabric

-

Towel Bale Press Machine

The Towel Bale Press Machine is used to compress and package towels into bales for efficient storage and transportation. Designed for industrial use, it ensures consistent compression and durability, facilitating easy handling and reducing shipping costs. Ideal for large-scale textile operations aiming for efficient packaging and distribution.

towel bale press machine, fabric compression, industrial, packaging, efficient, durable

-

Towel Checking

Towel Checking is a quality control process focused on inspecting towels for defects and ensuring consistency in fabric quality. This involves examining aspects such as stitching, texture, and durability to ensure that each towel meets the required standards before it reaches consumers. Essential for maintaining high quality and customer satisfaction in textile products.

Towel Checking towel checking, quality control, inspection, fabric, durability, consistency

-

Twisting Machine/ Doubling

A Twisting Machine, also known as a doubling machine, is used to twist multiple yarns together to create a stronger and more uniform final product. This process enhances yarn strength and consistency, making it suitable for various textile applications. Ideal for preparing yarns for weaving or knitting, the machine ensures that the doubled yarn meets the required quality standards and performance characteristics.

Twisting Machine, Doubling twisting machine, doubling, yarn twisting, textile processing, strength, uniformity

-

Warping Machine

A Warping Machine is used in textile manufacturing to prepare yarns for the weaving process. It aligns and winds multiple yarns onto a warp beam, creating a warp sheet that is ready for weaving. This machine ensures the yarns are evenly tensioned and accurately arranged, which is crucial for producing high-quality woven fabrics. Warping machines are essential for efficient and precise setup in the weaving process, improving overall fabric production and consistency.

Warping Machine, warping machine, textile machinery, yarn preparation, warp beam, weaving process, warp setup

-

Warping- Sectional Warping Machine

A Sectional Warping Machine is used in textile manufacturing to prepare yarns for weaving by arranging them in sections on a warp beam. This machine divides the yarns into sections, allowing for precise control and alignment of the warp threads. It ensures even tension and accurate setup for the weaving process, resulting in high-quality woven fabrics. Sectional warping is particularly useful for creating complex and multi-colored patterns, providing a reliable and efficient method for preparing yarns for large-scale weaving operations.

Warping, Sectional Warping Machine, sectional warping machine, warping technology, textile machinery, yarn preparation, sectional warping, warp beam

-

Washing Machines

Washing Machines are designed for cleaning fabrics and textiles efficiently. They come in various sizes and capacities, suitable for both industrial and domestic use. These machines automate the washing process, offering features such as adjustable cycles and temperature controls to ensure thorough and gentle cleaning of various materials. Essential for maintaining fabric quality and cleanliness in both small and large-scale operations.

Washing Machineswashing machines, fabric cleaning, industrial, efficiency, capacity, automation

-

Weaving

Weaving is the process of interlacing two sets of yarns—warp (longitudinal) and weft (transversal)—to create fabric. This technique is performed using a loom, which can be manual or automated, and involves various types of weaves such as plain, twill, and satin. Weaving is fundamental in textile production, enabling the creation of diverse fabric types and patterns for various applications in clothing, upholstery, and industrial products.

weaving, textile production, fabric creation, warp and weft, loom, industrial

-

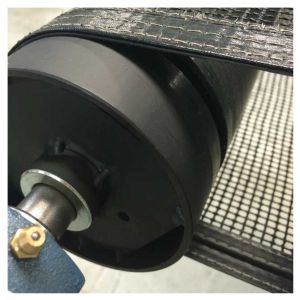

Winding- Auto Cone Winder

The Auto Cone Winder is an advanced machine designed for automatically winding yarn onto cones. It ensures precise and efficient winding, reducing manual labor and improving yarn quality. This machine is essential in textile manufacturing for processing yarns into manageable and ready-to-use cones, optimizing production speed and consistency in yarn winding operations.

Winding, Auto Cone Winder, cone winder, auto cone winder, yarn winding, textile machinery, automatic winding, cone winding machine, yarn processing

-

WInding- Cone Winder Machine

A Cone Winder Machine is designed for winding yarns onto cone-shaped spools. It automates the winding process to ensure consistent tension and uniform winding, which is essential for high-quality yarn production. This machine is commonly used in the textile industry to prepare yarns for further processing or use in manufacturing, optimizing efficiency and accuracy in yarn handling. The cone winder helps streamline production, reduce manual labor, and maintain the integrity of the yarn.

WInding, Cone Winder Machine, cone winder machine, yarn winding, textile machinery, cone winding, yarn processing, winding technology

-

Winding- Hard Winding

Hard Winding is a process where yarn is wound tightly onto a spool or cone, creating a compact and firm package. This method is ideal for yarns that require high tension and stability during subsequent textile processes. Commonly used in industrial settings, hard winding ensures efficient storage, transport, and further processing of yarns, maintaining their quality and consistency.

winding, hard winding, yarn preparation, tight winding, high tension, industrial

-

Winding- Precision Winding

Precision Winding is a process focused on achieving accurate and consistent yarn tension during winding. This method ensures high-quality yarn preparation by maintaining uniform winding and minimizing defects. Ideal for industrial applications, precision winding enhances the reliability and performance of yarns in various textile processes, providing a solid foundation for further manufacturing stages.

Winding, Precision Winding winding, precision winding, yarn preparation, accurate tension, high-quality, industrial

-

Winding- Soft Winding

Soft Winding is a process designed to handle yarns with gentle tension, ensuring that they are wound without causing stress or damage. This method is ideal for delicate or high-value yarns, providing a soft and uniform winding that preserves the yarn's quality and texture. Commonly used in industrial settings, soft winding helps maintain the integrity of yarns for subsequent textile processes and applications.

winding, soft winding, yarn preparation, gentle tension, fabric care, industrial

-

Winding- Ssm Cw2-w

The SSM CW2-W is a versatile and precise winding machine used in textile production for winding yarns with consistent tension and smoothness. This machine is designed for high efficiency, making it suitable for various yarn types and applications. Known for its reliability, the SSM CW2-W helps maintain yarn quality and enhances productivity in industrial textile processes.

Winding, Ssm Cw2-w winding, SSM CW2-W, yarn winding, precision, versatile, textile machinery

-

Winding- Ssm Cw8-w

The SSM CW8-W is a precision winding machine designed for high-efficiency yarn winding in textile production. This machine offers advanced control features to ensure consistent yarn tension and smooth winding, making it ideal for preparing yarns for knitting, weaving, or further processing. Known for its durability and versatility, the SSM CW8-W enhances productivity and maintains yarn quality in industrial applications.

Winding, Ssm Cw8-w winding, SSM CW8-W, yarn winding, precision, high-efficiency, textile machinery

-

Winding- Ssm PS6plus-w

The SSM PS6plus-W is a high-speed winding machine designed for precise and efficient yarn winding. This advanced system ensures uniform yarn tension and smooth winding, making it ideal for preparing yarns for further processing in textile production. Known for its reliability and versatility, the SSM PS6plus-W enhances productivity and maintains the quality of yarns in industrial applications.

winding, SSM PS6plus-W, yarn winding, precision, high-speed, textile machinery

-

Winding- Step Precision Winding

Step Precision Winding is a specialized technique in yarn winding that focuses on achieving high precision and accuracy. This process involves carefully controlling the winding stages to ensure consistent tension and uniform winding, resulting in high-quality yarn with minimal defects. This technology is crucial for applications requiring precise yarn characteristics, enhancing performance and reliability in textile manufacturing.

Winding, Step Precision Winding, precision winding, step precision winding, yarn winding, textile machinery, precision winding, winding technology, yarn processing

-

Winding: Fadis P300

The Fadis P300 is a high-speed winding machine designed for precise and efficient yarn winding in textile production. It features advanced technology for consistent tension control and smooth winding, making it suitable for a wide range of yarn types. The Fadis P300 enhances productivity and ensures high-quality yarn preparation for subsequent textile processes.

Winding, Fadis P300 winding, Fadis P300, yarn winding, precision, high-speed, textile machinery

-

Yarn Lab

A Yarn Lab is a specialized facility dedicated to testing and analyzing yarn for various properties, such as strength, texture, and composition. It focuses on quality control and research, ensuring that yarn meets industry standards and performs well in textile applications. Essential for developing new yarns and maintaining high quality in fabric production.

Yarn Lab , textile testing, quality control, yarn analysis, fiber properties, research

-

Yarn Receiving & Storage

Yarn Receiving & Storage refers to the processes involved in handling and storing yarns upon delivery to ensure they remain in optimal condition for use. This includes inspecting received yarns for quality and accuracy, organizing them in a controlled environment to prevent damage, and managing inventory efficiently. Proper yarn storage is crucial for maintaining yarn quality, preventing issues such as tangling or moisture damage, and ensuring smooth operations in textile production.

Yarn Receiving, Storage, yarn receiving, yarn storage, textile inventory, yarn management, material handling, yarn warehouse

Name: Adeel Paul

Address: F143 S.I.T.E., karachi

Website: https://paultextile.com/oldsite/newsite/

Profile URL: https://towelassociation.com/paul textile towel industries

Certifications: